Project Analysis

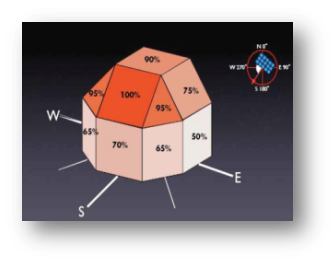

At this stage the product development department analyse the requirements and architectural drawings of the project sent by the client.

Expositions, shadings, usable surfaces and the fastening system are analyzed to used to get a picture of the feasibility of the request.

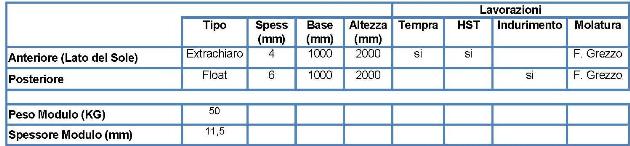

Sizing Glassi

Dopo la prima analisi del progetto si procede al dimensionamento dei vetri da un punto di vista strutturale:

Dopo la prima analisi del progetto si procede al dimensionamento dei vetri da un punto di vista strutturale:

vengono definiti misure, tipologie, caratteristiche e lavorazioni dei singoli vetri calcolando anche pesi e spessori.

I due vetri che compongono il vetro strutturale fotovoltaico subiscono differenti tipi di lavorazione:

- Vetro esterno esposto ai raggi solari le cui facce sono perfettamente piane e parallele con bassissimo contenuto di ferro (extrachiaro) ad altissima trasmissione di luce non inferiore al 92%, con lavorazione di bordo molatura a filo lucido e/o filo grezzo, temperato e trattamento HST (Heat Soak Test) con uno spessore minimo e sufficiente a sopportare urti accidentali e resistente alle condizioni metereologiche più avverse ( vento forte, grandine di grosse dimensioni)

- Vetro interno le cui facce sono perfettamente piane e parallele, può essere extrachiaro o float a discrezione del progetto e del campo d'applicazione, con lavorazione di bordo molatura a filo lucido e/o filo grezzo, a seconda della destinazione ( float, indurito , temperato + HST) di spessore minimo e sufficiente a sopportare i carichi permanenti accidentali e se richiesto il calpestio.

La stratifica viene effettuata con due strati di PVB Solar (polivinilbutirale) da 0,76mm ad alta trasparenza ed elevata resistenza all'umidità.

Di seguito un esempio di possibile dimensionamento vetri.

A questo punto si è pronti per l'adozione delle prassi progettuali necessarie per favorire la prestazione fotovoltaica.

PV Configuration

Is then studied if necessary a possible design of screen printing to give homogeneity to the project.

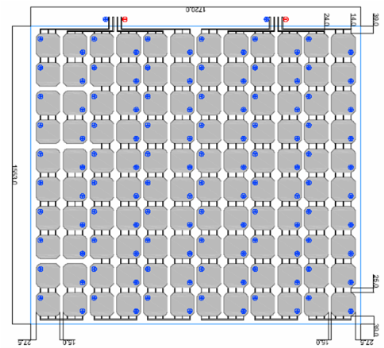

Photovoltaic configuration consist on the design of the photovoltaic component of glass and provides the definition of the type, disposition and number of PV cells (No. Lists and No. of cells per list). The mutual distance between cells determines the transparency of the photovoltaic glasses.

Photovoltaic cells interposed in the glass can be of several types and sizes, either 5 '(125 mm) and 6 ' (156 mm).

Depending on typology you have different performance characteristics of power: Pmax (W), Isc (A) Voc (V), Ipm (A), Vmpp (V), FF, Eff (%).

Photovoltaic cells can be mono or polycrystalline silicon's, blue or colored. In addition to crystalline silicon cells are also available modules with thin film amorphous silicon (a layer of photovoltaic material deposited directly on the glass) with different levels of transparency. These modules are fixed size and not personalizable and their efficency compared to the PV cells is very low.

Below a series of cell that EnergyGlass uses to offer a wide set of solutions concerning power and design

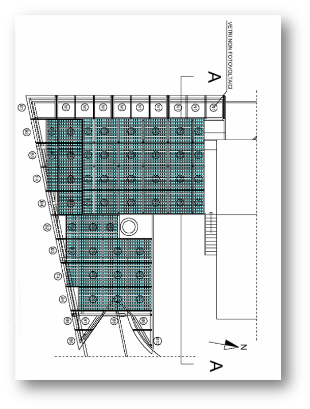

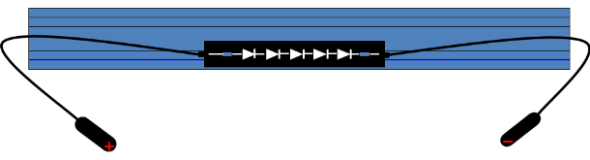

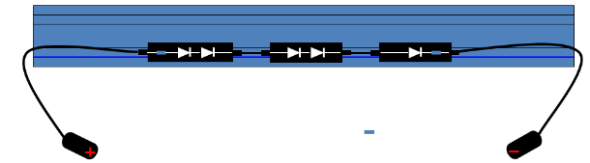

Design of wiring

- Possible areas of partial shading of the PV glass.

- Maximum number of cells per bypass diode.

- Voltages and currents of module.

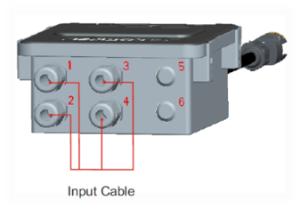

- The number and type of junction boxes is defined in the planning stages.

In the example below are placed two junction boxes where are needed 6 bypass diodes of 6 A and a maximum voltage of 100 V.

Junction boxes

Flexible configuration:

- Rails

- diodes

- bridges

- connections

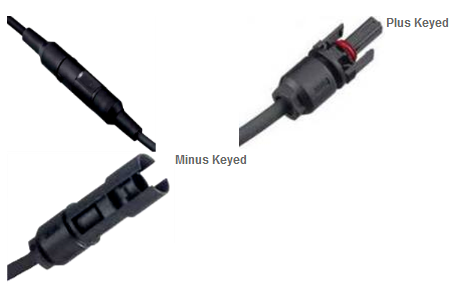

Connection typologies

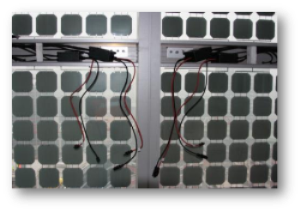

The PV glasses can be installed in double glazing therefore it is necessary to position the junction box in an accessible area. For this reason,will be used cables IP 67 to connect the ribbon that comes out of the glass to the boxes where are positioned bypass diodes. From the boxes will come out two cables for the connections to other modules

Edge Connectors

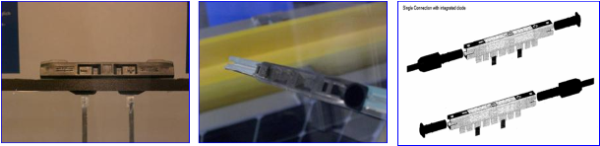

For a better integration, the PV glasses will be equipped with side connector instead of rear junction box to permit the inclusion in one side of the glazing and in the other to insert the connectors in the profile of containment of the glass.

The edge-connector to be used will be the one produced by Tyco Inc. as those shown below.

The final measures will be announced shortly, those available today are:

- Width: 15 cm

- Height: 1.5 cm

- Depth: 1.5 cm

The connectors may include diodes for the creation of substrings

Connection examples

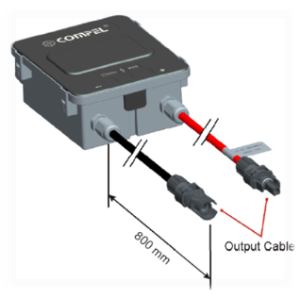

Remote Junction Box

In case you can not use the classical junction box as in case of PV insulating glass and when the frame does not allow you to place the lateral connectors is it possible to use the remote box in a separate location from the glass. It can be mounted or placed in the structure or in hidden areas.

Examples of application of remote junction box